100kg Welding Positioner – Heavy-Duty & Precision Rotation

- Home

- 100kg Welding Positioner – Heavy-Duty & Precision Rotation

Products

Get a Quote

Need more help?

The company always adheres to the spirit of honesty and trustworthiness.

+8618678896622

zhangrui018@gmail.com

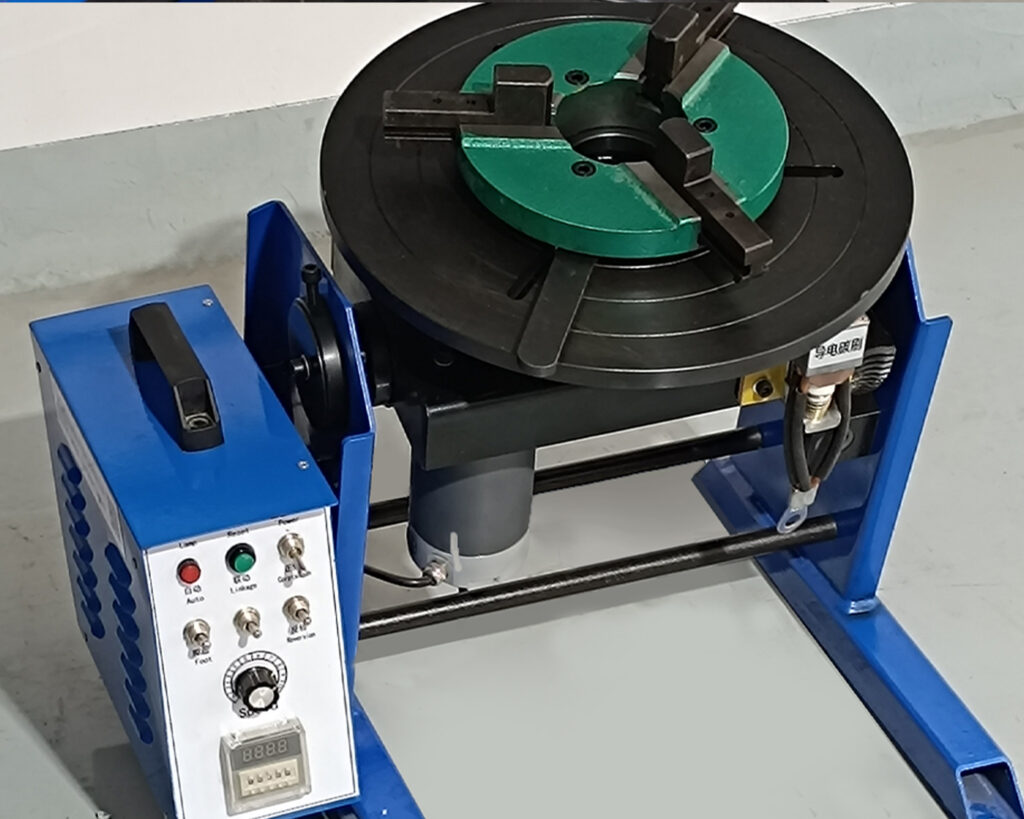

100kg Welding Positioner – Heavy-Duty & Precision Rotation

100kg Welding Positioner for precise rotation & tilting. Ideal for arc, MIG, TIG welding. Heavy-duty, durable design boosts productivity

100公斤变位机

BWJ-100 positioner

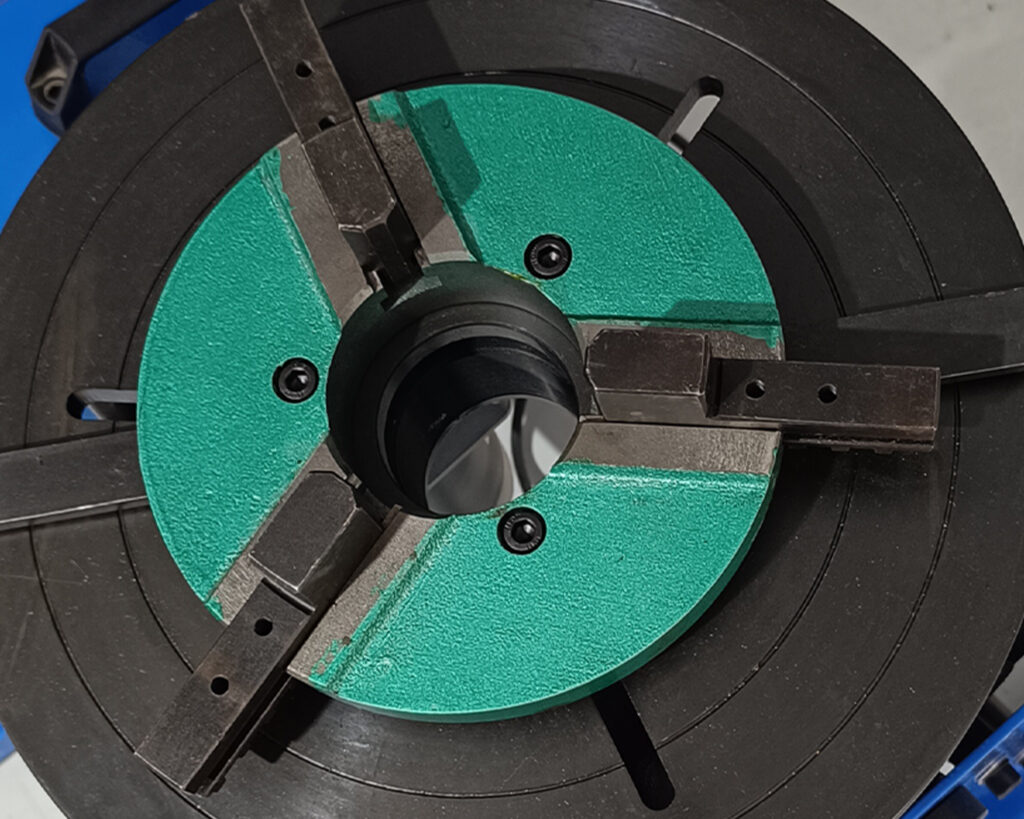

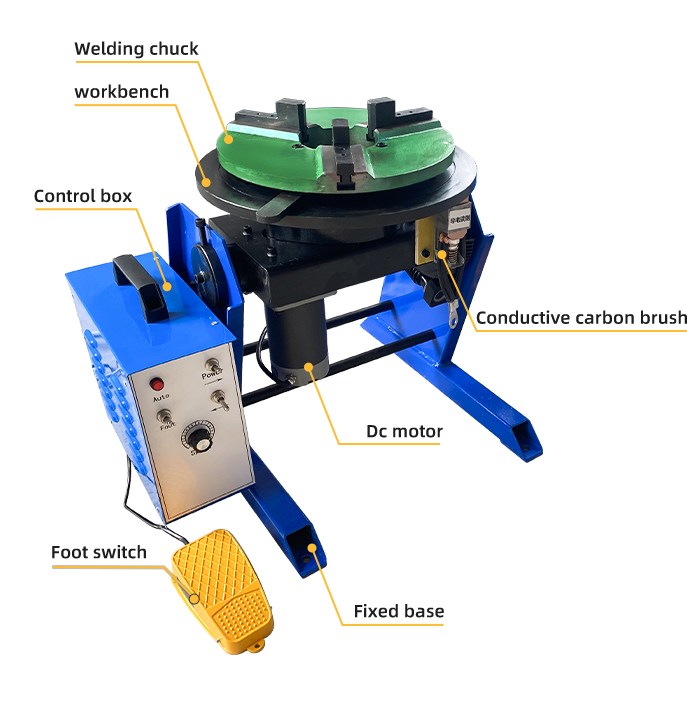

- Workpiece Setup and Positioning

Place the workpiece securely onto the chuck. The chuck’s quick – acting mechanism clamps the workpiece firmly. Using the hand – operated worm, tilt the workbench precisely. This positions the weld seam in an ideal flat welding orientation, facilitating excellent weld pool fusion and resulting in aesthetically pleasing and high – quality weld formations. - Enhanced Welding Tool Adjustability

Opt for the welding torch bracket. This accessory not only fixes the welding torch in place but also enables seamless adjustment of the torch’s position relative to the weld seam. This flexibility ensures accurate and efficient welding. - Advanced Workpiece Support

Equip the positioner with an optional pneumatic thimble. The thimble performs multiple crucial functions: it positions the workpiece accurately, presses it tightly to prevent movement, and rotates in sync with the workpiece. This ensures that the workpiece rotates concentrically with the weld seam, maintaining consistent welding conditions. - Intuitive Control Box Features

The control box features a knob for stepless speed regulation. Operators can easily switch between forward and reverse rotation, and choose between foot – controlled operation and automatic rotation. An optional timing function is available, along with a signal line for seamless integration with the welding machine. By setting the time and speed parameters, automatic welding becomes a straightforward process. - PLC Touch – Screen Interface

The PLC touch – screen interface offers unparalleled control. Users can set the rotation angle and speed with precision, and control the pneumatic torch holder with a single touch. The interface also has a parameter storage function, allowing for quick recall of frequently used settings.

| Model number | BWJ-100 |

| Load (horizontal/vertical) | 100/50KG |

| Through-hole diameter | 65mm |

| Motor power | 120W |

| Disk diameter | 360mm |

| Rotational speed | 0.5-5r/M |

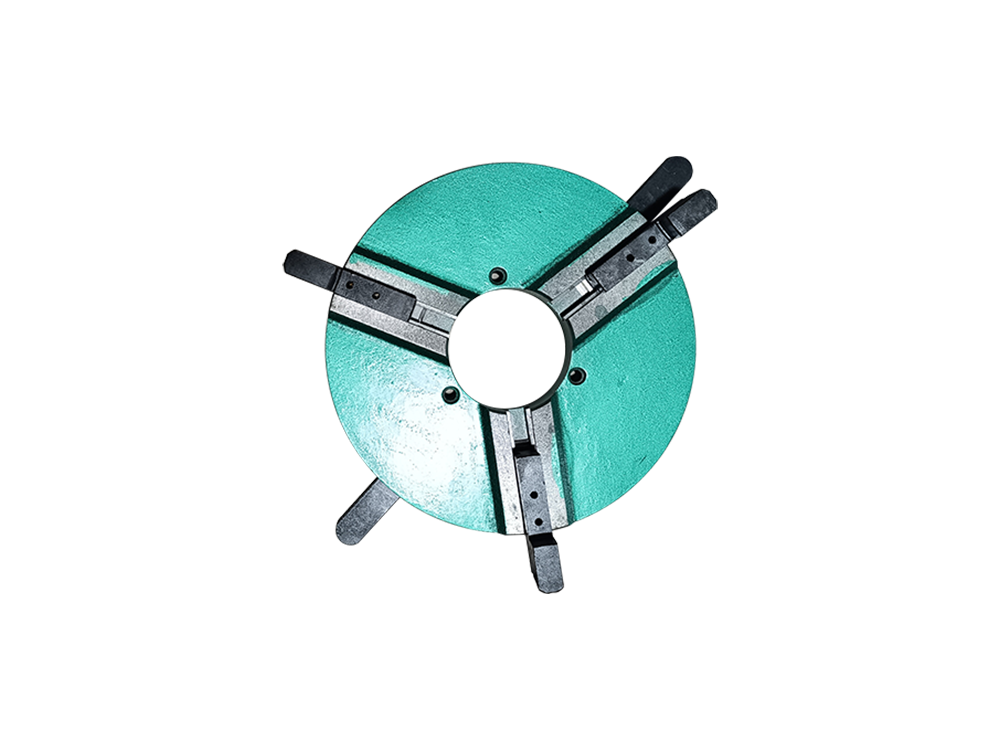

| Adaptive chuck | 200/300mm |

| Overall dimension | 500*415*450mm |

产品细节

Product details

Multiple configuration

The welding chuck and gun adjusting mechanism can be configured to fix the welding distance position and adjust the relative position of the workpiece and the welding gun

Wear turbine handle

Table can be freely turned 0-90 °

Easy to operate and adjust quickly

Electric rotation

Use high quality materials

Electric rotary table

Saving time and labor welding stability

Extra-large through-hole

Optional through hole

Suitable for welding of long pipe parts

Preferred brand motor

产品解析/尺寸

Product analysis/dimensions

可搭配设备

Configurable equipment

XH-200 Chuck

XH-300 Chuck

Pneumatic tailstock

Pneumatic gun holder

Welding torch holder

Welding control box

TJ-400 roller bracket

TJ-500 roller bracket

现场实拍

Live shooting