Pipe Flange Welding Equipment – High Precision & Durable

- Home

- Pipe Flange Welding Equipment – High Precision & Durable

Products

Get a Quote

Need more help?

The company always adheres to the spirit of honesty and trustworthiness.

+8618678896622

zhangrui018@gmail.com

Pipe Flange Welding Equipment – High Precision & Durable

Argon arc automatic welding pipe flange bellows automatic wire filling oscillating argon arc automatic welding equipment

管法兰自动焊

Automatic welding of flanges

Cantilever – Type Automated Pipe Welding Machine

The cantilever – type automated pipe welding machine is an advanced welding equipment for pipe flanges4.

Scope of Application4: It is suitable for the automatic welding of pipelines with multiple welds and long pipeline segments, and can be used for continuous welding of multiple welds. It can not only perform pipe – pipe welding and pipe – flange welding but also pipe – elbow welding. It supports various welding methods such as argon arc welding, carbon dioxide – shielded welding, and submerged – arc welding, with good flexibility in welding selection.

Product Features: The machine consists of an automatic pipe welding machine, a positioner, a mobile welding trolley, and a supporting welding trolley4. It has the characteristics of being able to perform multi – section welding without the need for frequent movement of pipes and fittings, and can weld flanges, elbows, tees, and other pipe fittings, which is a multifunctional automatic pipe welder4. The welding power source of the automatic pipe welder can be customized according to needs4.

◆ Flange automatic welding equipment is mainly considered in three aspects, one is whether the host can be changed, whether the rotation can be low speed and smooth, especially the large diameter, the second is the stability of the welding gun, including the Angle of the welding gun can be flexibly adjusted, can be automatically lifted, convenient loading and unloading parts, whether the weld width is equipped with a wobbler, and the last one is the welding machine. Weld forming, splash size, energy saving, after-sales protection, etc., our company is standard with Aotai or Shanghai General welding machine.

◆ According to the size of the pipe and flange, the amount of processing per day, the degree of skilled operation of the workers have the following forms to choose.

| Model number | ZDH-300 |

| Chuck support | 20-500mm |

| Positioner horizontal load | 300KG |

| Positioner carries vertical load | 150KG |

| Turnover Angle | 0-90° |

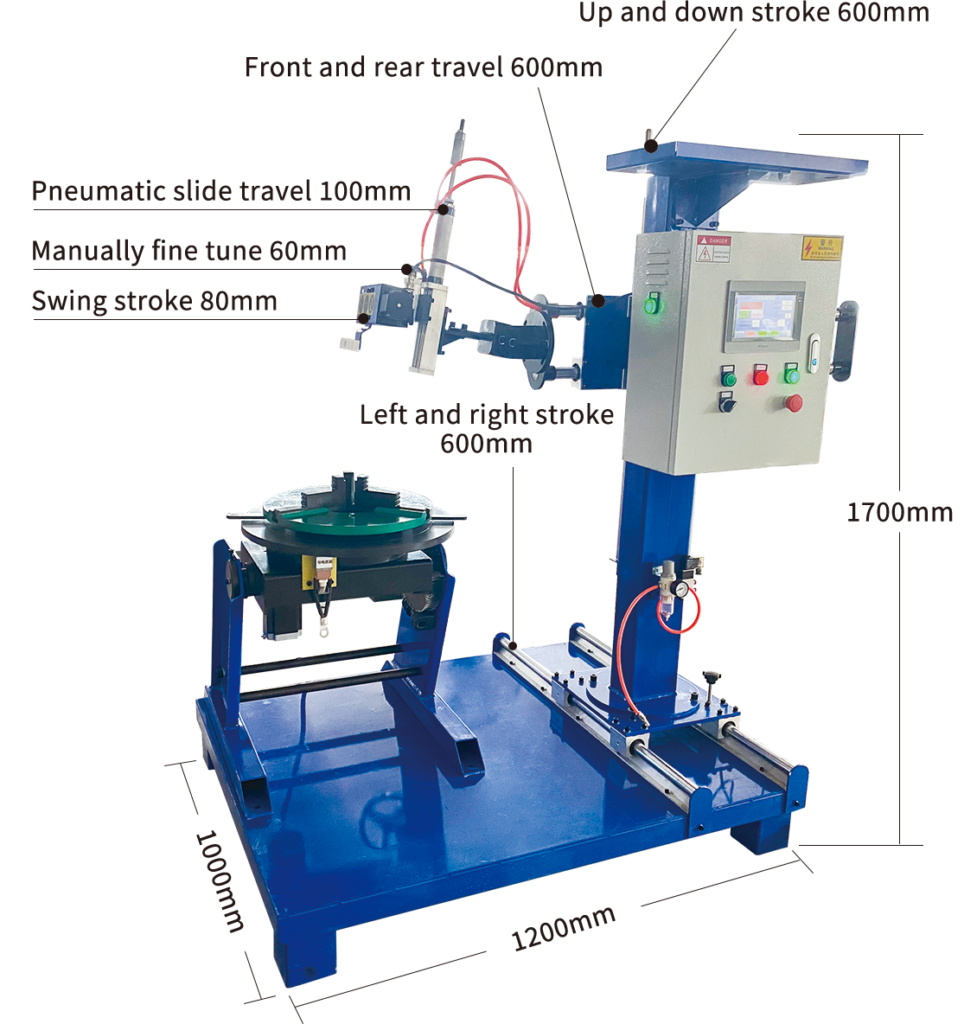

| Pneumatic slide travel | 100mm |

| Manual fine-tuning | 60mm |

| Swing stroke | 80mm |

| Left and right stroke | 600mm |

| Anteroposterior stroke | 600mm |

| Up and down stroke | 600mm |

| Overall dimension | 1200*1000*1700mm |

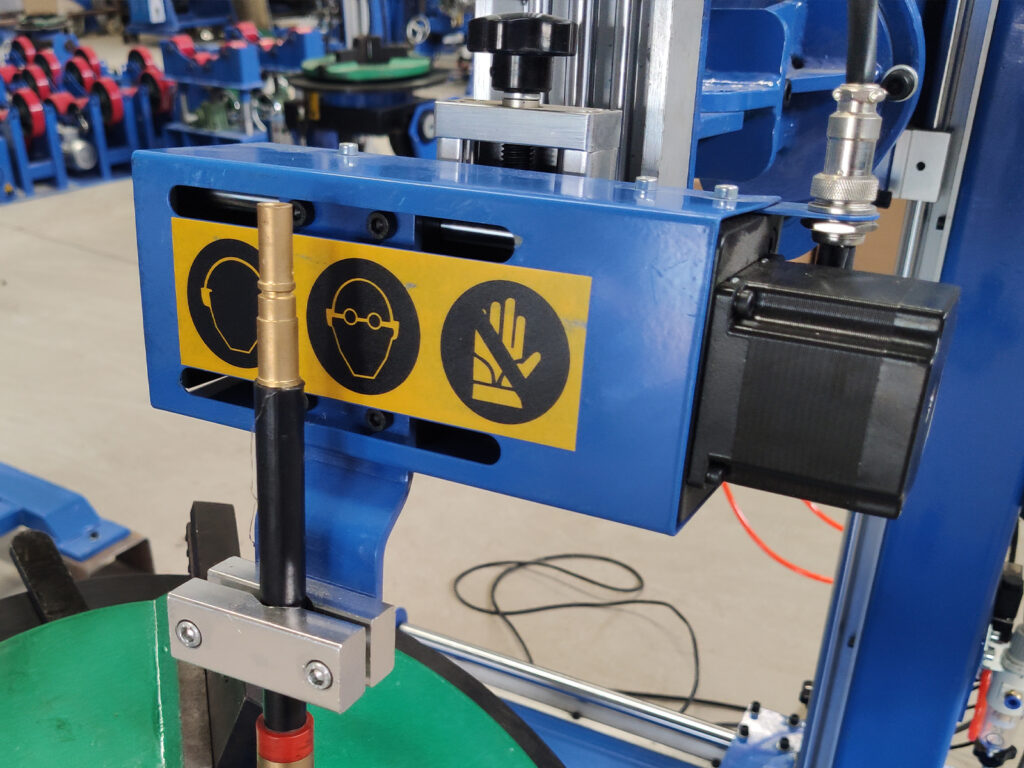

产品细节

Product details

PLC control box

PLC touch screen control box

Overall control one-key operation

Regulating hand wheel

Welding gun position up and down, front and rear hand wheel adjustment (suitable for different sizes of workpieces)

Precision pneumatic slide

Loading and unloading work is convenient

Airflow can be regulated

Repeated positioning accuracy

Cross sliding table

Manual fine-tuning

Torch height

Can be manually adjusted up and down

Welding oscillator

Configure welding wiggler

Weld fish scale

Precision rail

Easy to move

Fixed locking

产品解析/尺寸

Product analysis/dimensions

现场实拍

Live shooting