CO2/MIG Auto-Welding Equipment | Industrial Grade

- Home

- CO2/MIG Auto-Welding Equipment | Industrial Grade

Products

Get a Quote

Need more help?

The company always adheres to the spirit of honesty and trustworthiness.

+8618678896622

zhangrui018@gmail.com

CO2/MIG Auto-Welding Equipment | Industrial Grade

CO2 welding rotator for pipes & tanks – self-aligning rollers ensure smooth rotation with MIG/MAG welding, ideal for high-efficiency fabrication.

CO2自动焊

Laser automatic welding

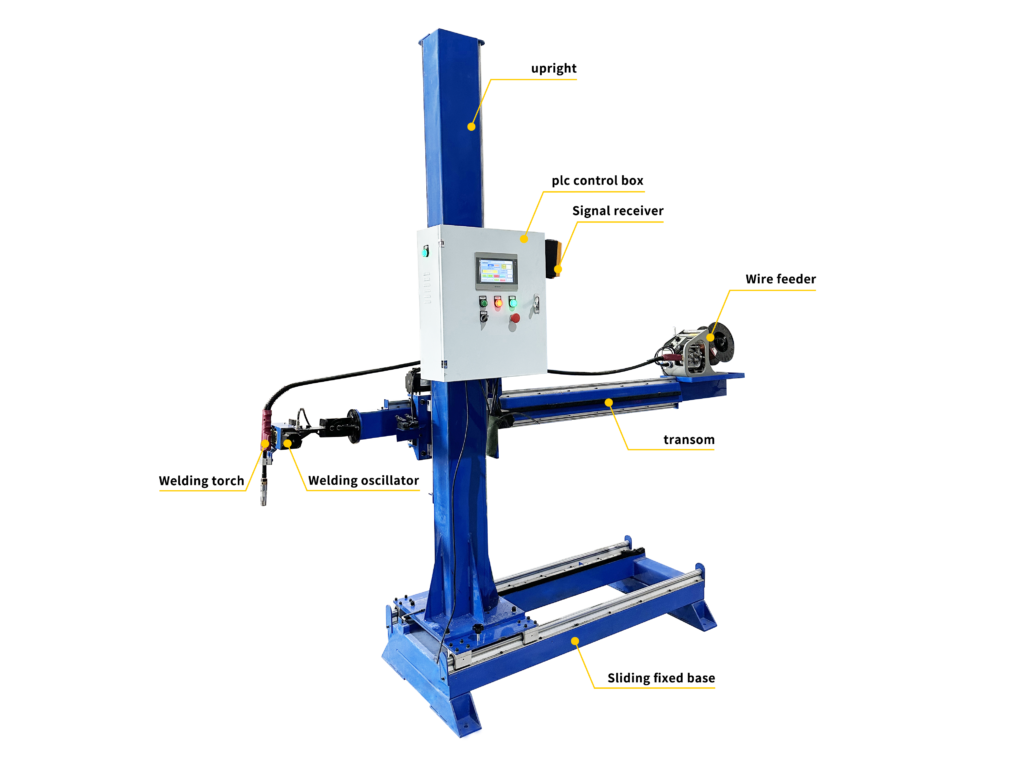

Structural Features

- Heavy – Duty Frame: The rack is constructed with a robust steel frame that can withstand the weight of the welding power source, wire feeder, and other associated equipment. It is designed to have a high load – bearing capacity, ensuring stability during operation.

- Adjustable Height: The height of the equipment rack can be easily adjusted to meet the specific requirements of different welding tasks and operator preferences. This adjustability helps to improve the ergonomics of the welding workstation, reducing operator fatigue.

- Integrated Wire Feeder Mount: There is a dedicated mount for the wire feeder, which is designed to hold the wire feeder in a stable position and ensure smooth wire feeding. The mount allows for easy access to the wire feeder for maintenance and adjustment.

- Gas Cylinder Holder: The rack is equipped with a gas cylinder holder that can securely hold the CO₂ gas cylinder. It has a safety – locking mechanism to prevent the gas cylinder from tipping over, ensuring the safety of the welding operation.

The welding machine produced by our company is widely used in C02/ plasma welding/laser/argon arc/submerged arc welding

Standard welding wiggler, PLC touch screen control box, wireless remote control; Argon arc automatic welding is equipped with automatic arc voltage adjustment system, argon arc welding wire feeding system, etc. The whole machine control realizes automatic welding

Can be combined with welding positioner/welding turntable/welding roller frame to achieve linkage control.

| Model number | Beam expansion velocity | Beam dimension | Column section dimension | Overall dimensions:m/weight:kg | |||

| stationary | Rotary (manual/electric) | Trolley walking type | |||||

| minitype | ZDH-1.5*1.5 | 140-1400mm/min | 150*100*6mm | 200*150*6mm | 2.3*0.4*2.8(200kg) | 2.3*0.6*2.9(300kg) | Less use |

| ZDH-2*2 | 140-1400mm/min | 150*100*6mm | 200*150*6mm | 2.8*0.4*3.3(250kg) | 2.8*0.6*3.4(350kg) | Less use | |

| light-duty | ZDH-2*2 | 140-1400mm/min | 250*100*6mm | 400*300*6mm | 4*0.6*4(1500kg) | 4*1. 3*4.2 (1700kg) | 4*2.5*4.6(2500kg) |

| ZDH-3*3 | 140-1400mm/min | 250*100*6mm | 400*300*6mm | 5*0.6*5(1700kg) | 5*1.3*5.2(1900kg) | 5*2.5*5.6(2700kg) | |

| ZDH-4*4 | 140-1400mm/min | 250*100*6mm | 400*300*6mm | 6*0.6*6(2000kg) | 6*1.3*6.2(2200kg) | 6*2.5*6.6(3000kg) | |

| Heavy type | ZDH-4*4 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 6.2*0.7*6.2(3200kg) | 6.2*1.3*6.4(3400kg) | 6.2*2.5*6.8(4400kg) |

| ZDH-5*5 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 7.2*0.7*7.2(3500kg) | 7.2*1. 3*7.4(3700kg) | 7.2*2.5*7.8(4700kg) | |

| ZDH-6*6 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 8.2*0.7*8.2(3800kg) | 8.2*1.3*8.4(4000kg) | 8.2*2.5*8.8(5000kg) | |

| ZDH-7*7 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 9.2*0.7*9.2(4100kg) | 9.2*1.3*9.4(4300kg) | 9.2*2.5*9 8(5300kg) | |

产品细节

Product details

PLC control box

Intelligent numerical control

Realize automatic welding

CO2 welding torch

CO₂ welding gun welding speed is much faster than traditional manual arc welding

CO₂ gas plays a protective role in the welding process, and the weld quality is good

Welding wire feeder

Automatic wire feed

Easy welding

Welding torch wiggler

Free adjustable stroke

Convenient for welding at different heights

产品解析

Product analysis

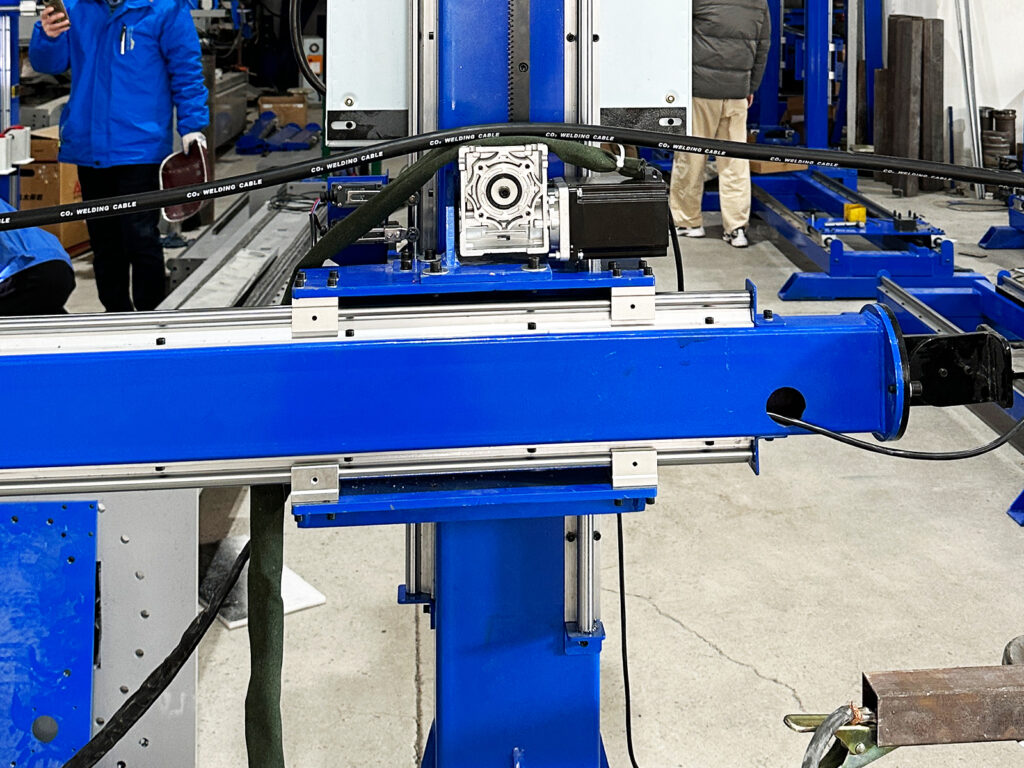

现场实拍

Live shooting