Submerged Arc Welding Machines | Automated SAW Operators

- Home

- Submerged Arc Welding Machines | Automated SAW Operators

Products

Get a Quote

Need more help?

The company always adheres to the spirit of honesty and trustworthiness.

+8618678896622

zhangrui018@gmail.com

Submerged Arc Welding Machines | Automated SAW Operators

Discover top-quality submerged arc welding (SAW) operator machines for efficient, high-precision welding. Boost productivity with automated SAW solutions.

埋弧焊接操作机

Submerged arc welding manipulator

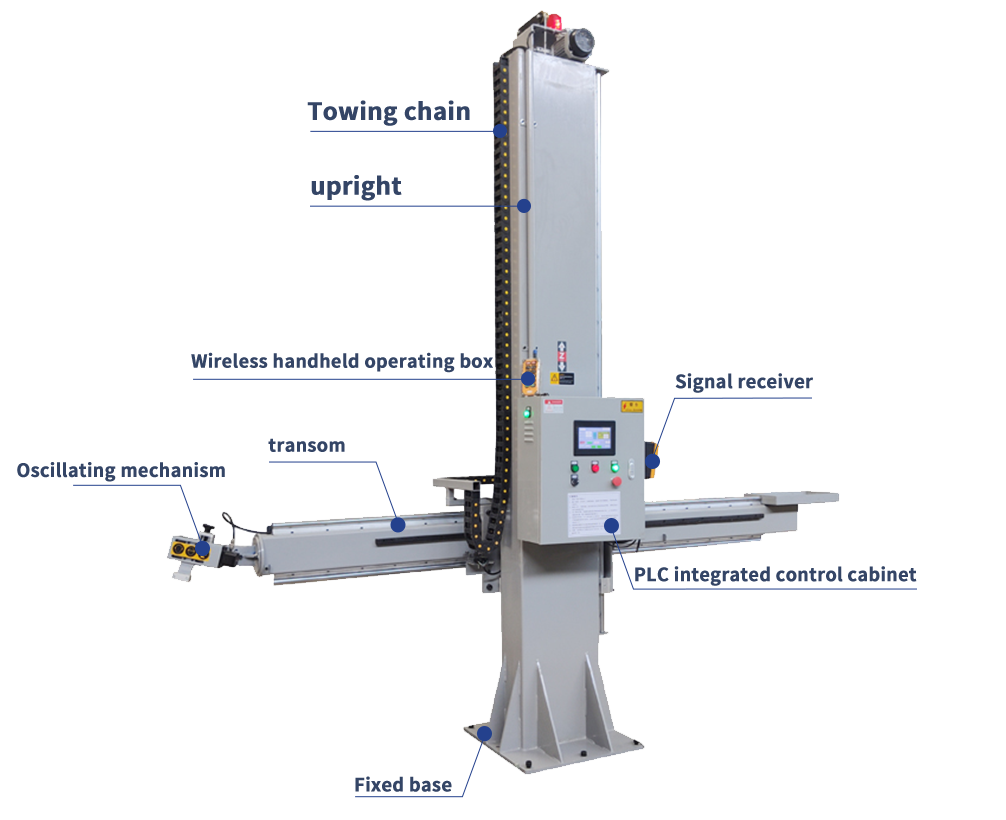

◆It is mainly composed of beam, towing chain, lifting system, column, guide rail, head and towing plate, hand operator, etc.

◆The machine head is installed on one end of the beam, the beam can be lifted up and down and telescoped around, and the column can be installed on the platform car through the turntable. The beam expansion speed is stable without crawling, and the downward deflection after extension is small.

◆Chain: The lifting of the beam is realized by pulling the chain. The equipment uses high-quality chain with high carrying capacity.

◆Safety claw: In an emergency, if the chain suddenly breaks. The safety claw can be quickly turned up and fastened in the square drop hole of the column to prevent the beam from continuing to fall and play a role in improving safety.

◆Wide application range, can be suitable for two protection welding/argon arc welding/submerged arc welding and other welding methods.

| Model number | Beam expansion velocity | Beam dimension | Column section dimension | Overall dimensions:m/weight:kg | |||

| stationary | Rotary (manual/electric) | Trolley walking type | |||||

| minitype | ZDH-1.5*1.5 | 140-1400mm/min | 150*100*6mm | 200*150*6mm | 2.3*0.4*2.8(200kg) | 2.3*0.6*2.9(300kg) | Less use |

| ZDH-2*2 | 140-1400mm/min | 150*100*6mm | 200*150*6mm | 2.8*0.4*3.3(250kg) | 2.8*0.6*3.4(350kg) | Less use | |

| light-duty | ZDH-2*2 | 140-1400mm/min | 250*100*6mm | 400*300*6mm | 4*0.6*4(1500kg) | 4*1. 3*4.2 (1700kg) | 4*2.5*4.6(2500kg) |

| ZDH-3*3 | 140-1400mm/min | 250*100*6mm | 400*300*6mm | 5*0.6*5(1700kg) | 5*1.3*5.2(1900kg) | 5*2.5*5.6(2700kg) | |

| ZDH-4*4 | 140-1400mm/min | 250*100*6mm | 400*300*6mm | 6*0.6*6(2000kg) | 6*1.3*6.2(2200kg) | 6*2.5*6.6(3000kg) | |

| Heavy type | ZDH-4*4 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 6.2*0.7*6.2(3200kg) | 6.2*1.3*6.4(3400kg) | 6.2*2.5*6.8(4400kg) |

| ZDH-5*5 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 7.2*0.7*7.2(3500kg) | 7.2*1. 3*7.4(3700kg) | 7.2*2.5*7.8(4700kg) | |

| ZDH-6*6 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 8.2*0.7*8.2(3800kg) | 8.2*1.3*8.4(4000kg) | 8.2*2.5*8.8(5000kg) | |

| ZDH-7*7 | 140-1400mm/min | 300*200*6mm | 500*300*6mm | 9.2*0.7*9.2(4100kg) | 9.2*1.3*9.4(4300kg) | 9.2*2.5*9 8(5300kg) | |

产品细节

Product details

Seiko quality

The equipment mainly consists of uprights

Cross arm, guide device

The lifting mechanism is composed

Multi-dimensional adjustment

Achieve the adjustment of the welding torch in the up-down, left-right and front-back directions

Stable operation

The transverse arm is also shaped by rectangular tube

Rectangular double guide rail structure

Can ensure the guide rail after machining

Straightness and stability of equipment operation

Excellent performance

A variety of specifications are available

The structure between the transverse arm and the beam and column is strong

Necessary to ensure accurate welding

Precise support and stability

产品解析

Product analysis