Название: Распространенные неисправности сварочного позиционера и способы их устранения

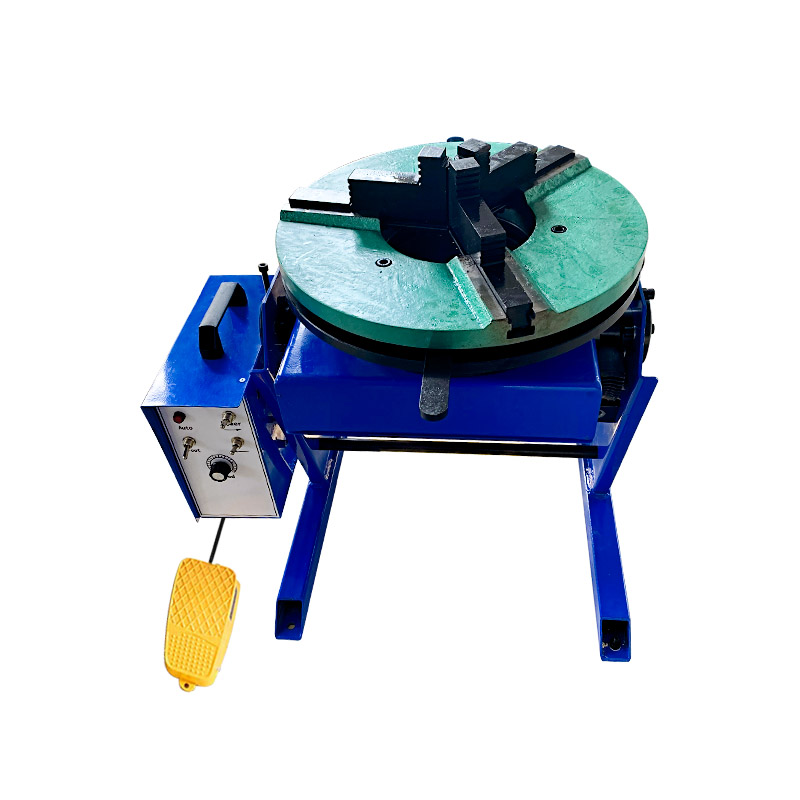

Сварочные позиционеры необходимы для повышения эффективности и точности сварочных работ. Однако, как и любое механическое оборудование, они могут столкнуться с проблемами в работе. Вот некоторые распространенные неисправности сварочных позиционеров и их решения, которые помогут вам поддерживать бесперебойную работу производства.

1. Позиционер не вращается

Возможные причины:

- Отказ источника питания

- Повреждение двигателя или приводной системы

- Ослабленная или поврежденная проводка

Решения:

1. Проверьте силовые соединения и убедитесь, что напряжение подается правильно.

2. Осмотрите двигатель и приводной блок на предмет износа или повреждений; при необходимости замените.

3. Подтяните или замените неисправную проводку.

2. Нерегулярные или рывковые движения

Возможные причины:

- Изношенные шестерни или подшипники

- Утечки в гидравлической/пневматической системе

- Несогласованные компоненты

Решения:

1. Смажьте или замените поврежденные шестерни и подшипники.

2. Проверьте гидравлические/пневматические линии на наличие утечек и устраните их.

3. Выровняйте компоненты позиционера для плавной работы.

3. Перегрев во время работы

Возможные причины:

- Чрезмерная нагрузка, превышающая допустимую

- Плохая вентиляция или неисправность системы охлаждения

- Непрерывная работа без перерывов

Решения:

1. Убедитесь, что вес заготовки находится в пределах номинальной мощности позиционера.

2. Очистите вентиляторы охлаждения и обеспечьте надлежащий поток воздуха.

3. При длительном использовании выдерживайте интервалы охлаждения.

4. Неисправность пульта дистанционного управления или автоматики

Возможные причины:

- Помехи сигнала или слабое соединение

- Неисправная панель управления или проблемы с ПЛК

- Неисправности датчиков

Решения:

1. Проверьте беспроводные/дистанционные соединения и устраните помехи.

2. При необходимости сбросьте или перепрограммируйте ПЛК.

3. Проверьте и замените неисправные датчики.

Советы по профилактическому обслуживанию

- Регулярно проверяйте электрические и механические компоненты.

- Держите позиционер чистым от пыли и сварочных брызг.

- Соблюдайте график смазки и обслуживания, указанный производителем.

Заблаговременное решение этих распространенных проблем позволит вам свести к минимуму время простоя и продлить срок службы сварочного позиционера.

Нужна профессиональная поддержка сварочного оборудования? Свяжитесь с нами для получения высококачественных сварочных позиционеров и квалифицированного устранения неисправностей!